Equipment Integration – Manufacturing Automation & System Integration

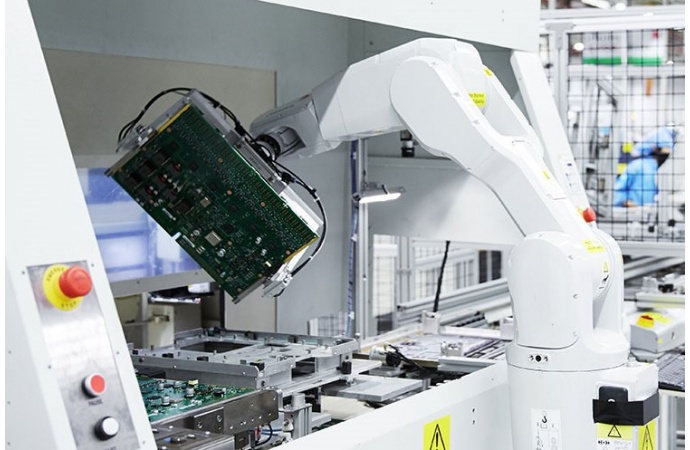

Integration of Equipment into Production Automation – The key to a high level of production automation

The integration of machines and equipment is the basis for fully automated production. The objective is to make machine data available plant-wide and to give production control systems (MES – Manufacturing Execution Systems) controlling access to machines and equipment.

Long time experience both in production IT and equipment automation, enables us to provide you with customised solutions. We will be glad to support you and your suppliers of machines and equipment during the integration process. Depending on the area of application, we use different technologies for machine integration. Please find an extract of our multiple successful used interface objects:

- Industrial Ethernet, TCP/IP, Fieldbus (Profibus, CAN-Bus, LON-Bus, Industrial Ethernet, MPI-Bus, H1-Bus etc.)

- PLC Interfaces e.g. S7, Beckhoff, etc.

- SECS/GEM, XML, SOAP, Message-Bus

- Database-oriented Interfaces

- Customized interface solutions

In addition to the use of standardised interfaces, we are also available with our expertise for developing customised interface solutions.

Make your machines more transparent. The better the performance of each machine, the merrier the production. Key questions are: how efficient are the machines, how is the utilisation of the machines, how reliabe are the operating machines?

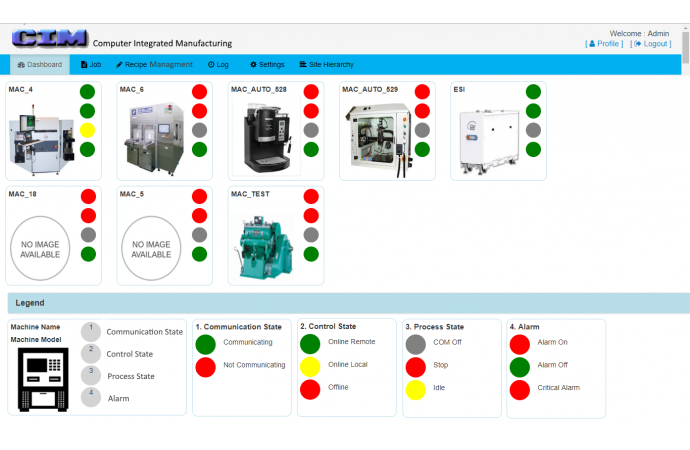

The analysis of machine data (MDE) and production data (PDE) will answer these questions. Our system solution TFM was developed especially for machine data acquisition and to visualise and analyse the data.

The main functions

- Online visualisation of the machine states

- Error acquisition and error statistics

- Machine state statistics

- Calculating the RAM indicators (Reliability, Availability, Maintainability)

- Reporting

The documentation of machine states and machine errors as well as the evaluation of machine reliability (RAM values) are the basis for analysing weak points and continuous improvement of the production process.

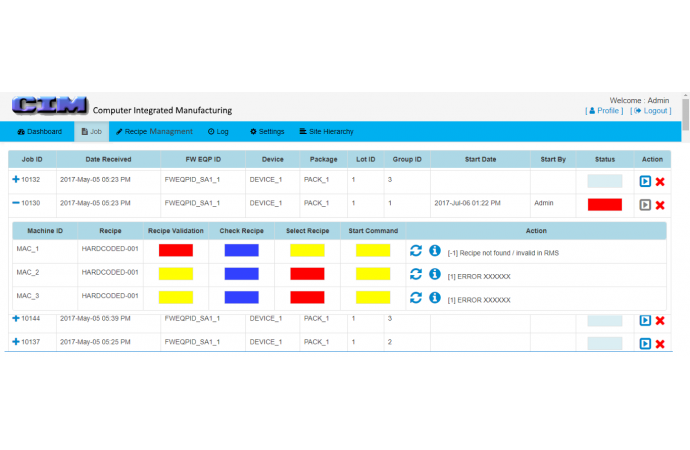

SECS/GEM – Equipment integration in the semiconductor industry

SECS/GEM represents a standardized interface between process equipment and factory-wide IT middleware for the semiconductor industry and electronics manufacturing. Our team has a wide experience of equipment integration and tested SECS/GEM-Driver.

We assist you in the field of

- Preparation for equipment integration

- Management of your equipment suppliers (Automation Capabilities Management – ACM)

- Implementation of Equipment Integration (EI)